Long standoffs are specialized fastening components designed to create significant spacing between surfaces, ideal for applications requiring extended vertical or horizontal gaps. Constructed from materials like stainless steel, carbon steel, or aluminum, these standoffs feature threaded shafts and durable structures to support heavy loads over long distances. Our company manufactures long standoffs using advanced CNC turning and cold-heading techniques, ensuring precise thread engagement and structural stability for reliable performance in industrial, architectural, and electronic applications.

The manufacturing process prioritizes material strength and dimensional accuracy. For heavy-duty applications, we use 10.9-grade carbon steel with zinc plating for corrosion resistance; stainless steel (304/316) is ideal for corrosive environments; and aluminum (6061) suits lightweight needs. CNC turning machines produce smooth shank surfaces and precise thread pitches, while heat treatment enhances tensile strength in steel variants. Each standoff undergoes load testing to validate its weight-bearing capacity and thread gauge checks to ensure compatibility with standard fasteners.

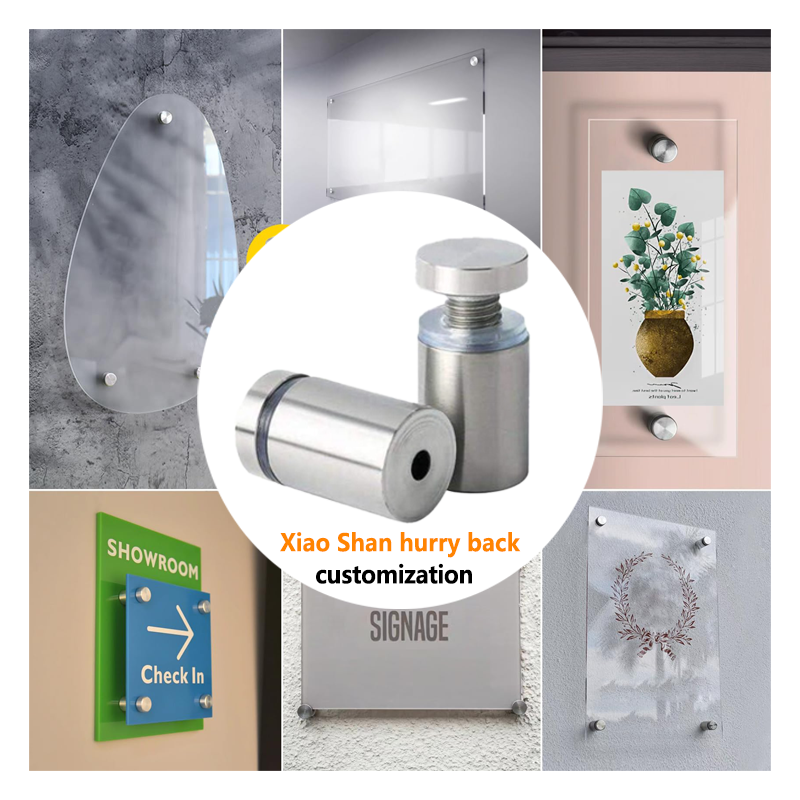

Long standoffs excel in applications like industrial machinery (spacing large components for ventilation), architectural installations (creating deep-set panels in facades), and data centers (mounting server racks with cable management gaps). Their extended length (ranging from 50mm to 300mm or more) allows for creative design solutions where standard standoffs fall short. We offer long standoffs in metric and imperial sizes, with custom lengths and thread configurations available to meet regional engineering standards and project-specific spacing requirements.

As a solutions-driven manufacturer, we provide fully customizable long standoff solutions. Clients can request unique materials (e.g., titanium for aerospace), specialized coatings (e.g., black oxide for aesthetics), or integrated features like through-holes for wiring. We support OEM projects with custom packaging and logo embossing, while wholesale pricing ensures cost-effectiveness for large-scale construction or manufacturing orders. Our global distribution network enables prompt delivery of certified products (ISO 9001, ASTM) to meet tight project deadlines.

Our long standoffs redefine spacing possibilities, combining structural integrity with design flexibility. They empower engineers to create innovative solutions in challenging applications, reducing the need for complex bracket systems. Contact us to explore how our custom long standoff solutions can meet your specific spacing requirements, backed by our expertise in precision fastening and commitment to global quality standards.