Insulating standoffs play a vital role in electrical and electronic systems by providing both mechanical support and electrical isolation between components. Constructed from high - performance insulating materials such as nylon, polyvinyl chloride (PVC), or fiberglass - reinforced plastics, these standoffs prevent the flow of electrical current, ensuring the safety and proper functioning of circuits. At [Company Name], we specialize in manufacturing insulating standoffs with exceptional precision, using injection molding and compression molding techniques to achieve consistent quality and dimensional accuracy.

The production of our insulating standoffs emphasizes material performance and manufacturing precision. We source top - grade insulating polymers that meet stringent electrical insulation standards, such as UL 94 for flammability ratings. During the molding process, precise temperature and pressure control are maintained to ensure that the standoffs have smooth surfaces, accurate thread forms (if threaded), and uniform wall thicknesses. Post - molding, the standoffs undergo rigorous testing, including dielectric strength testing to measure their ability to withstand high voltages without breakdown, and insulation resistance testing to confirm their electrical isolation capabilities. Additionally, mechanical tests, such as tensile and impact strength evaluations, are conducted to ensure they can withstand the rigors of installation and operation.

Insulating standoffs are widely used in a variety of applications. In electrical panels, they support and separate busbars, preventing short - circuits and ensuring reliable power distribution. For electronic devices, they mount circuit boards while keeping them electrically isolated from the metal chassis, protecting sensitive components from electrical interference. They are also essential in renewable energy systems, such as solar panel installations, where they provide both mechanical support and electrical insulation for the panels and wiring. Our insulating standoffs are available in different shapes, sizes, and thread configurations to suit diverse application requirements. We understand the global nature of electrical and electronics industries, and our products comply with international electrical safety standards, such as IEC 60950, making them suitable for use in markets around the world.

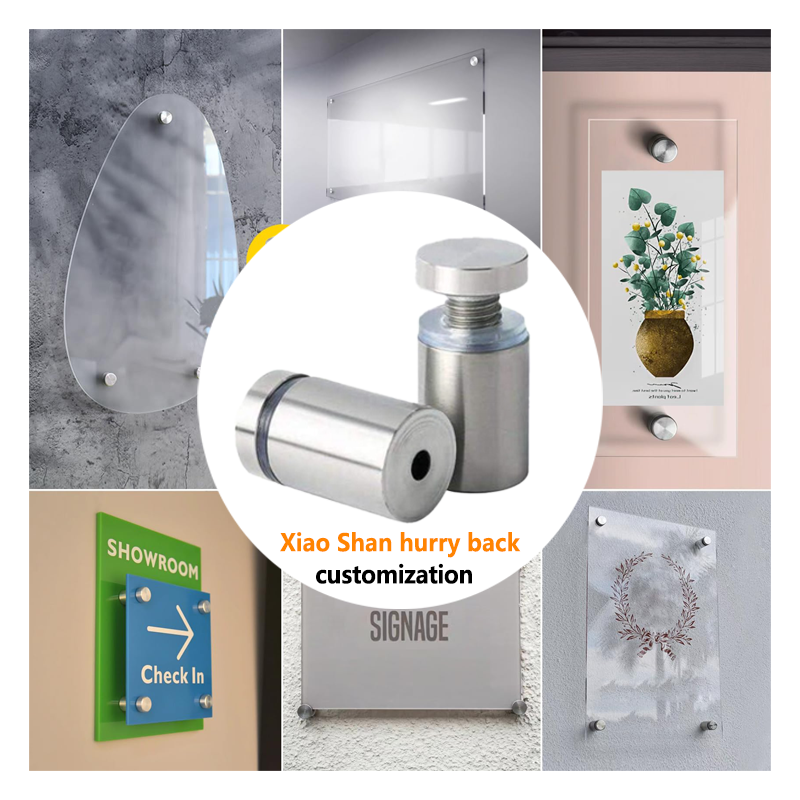

Customization is a key aspect of our insulating standoff offerings. Clients can request specific material formulations for enhanced chemical resistance or temperature tolerance, custom colors for identification purposes, or unique mounting features. We work closely with customers to develop tailored solutions, whether it's for a specialized electrical enclosure design or a unique electronic device. For large - volume orders, our wholesale pricing structure provides significant cost savings, and our efficient production processes ensure timely delivery. We also offer custom packaging options to protect the standoffs during transit and enhance brand presentation for distributors and OEMs.

Our insulating standoffs represent the perfect combination of electrical safety, mechanical reliability, and customization flexibility. By choosing our products, customers can be confident in the electrical isolation and support of their systems, reducing the risk of electrical failures and ensuring long - term performance. Reach out to us to discuss how our custom insulating standoff solutions can meet your specific electrical and mechanical requirements, backed by our in - depth knowledge of insulating materials and manufacturing expertise.