Locking standoffs are specialized fastening devices designed to prevent unintended loosening, providing secure and stable positioning of components in various applications. These standoffs incorporate innovative locking mechanisms, such as threaded collars, set screws, or spring - loaded designs, to ensure a tight and permanent connection. At [Company Name], we manufacture locking standoffs with a focus on precision engineering and high - quality materials, delivering products that offer exceptional reliability and performance.

The manufacturing process of our locking standoffs starts with material selection, typically including stainless steel, carbon steel, or brass, depending on the application requirements. For applications requiring high corrosion resistance, stainless steel is the preferred choice, while carbon steel offers high tensile strength for heavy - duty uses. Brass is selected when electrical conductivity or a decorative finish is needed. Once the material is chosen, the standoffs are formed using cold - heading or machining techniques to achieve the desired shape and dimensions. The locking mechanism is then integrated into the design with meticulous precision. For example, threaded collars are carefully threaded to ensure smooth adjustment and secure locking, while set screws are precisely positioned to provide maximum holding power. After assembly, each locking standoff undergoes comprehensive testing, including torque - to - loosen testing, vibration resistance testing, and fatigue testing, to ensure its locking effectiveness and durability.

Locking standoffs are widely used in industries where component stability is critical. In the electronics industry, they securely mount circuit boards, preventing movement and potential damage from vibrations. In mechanical equipment, they space and fix various parts, ensuring proper alignment and reducing the risk of component failure due to loosening. They are also essential in aerospace and automotive applications, where any component displacement could lead to serious safety issues. Our locking standoffs are available in a variety of sizes, thread types, and locking configurations to suit different application needs. We understand the global nature of these industries and ensure that our products meet international standards, such as ISO and SAE, for seamless integration into global manufacturing and assembly processes.

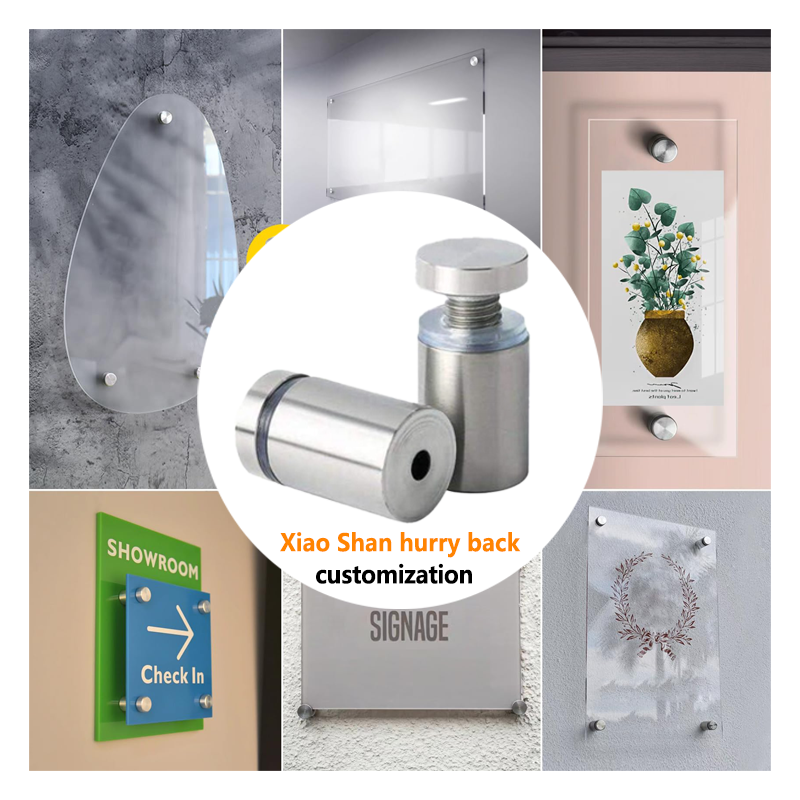

Customization is a key feature of our locking standoff offerings. Customers can request specific locking mechanisms based on their application requirements, such as a more secure double - locking system or a quick - release design. We also offer customization in terms of material grades, surface finishes, and dimensions. For branding purposes, we provide logo - embossing services on the standoff bodies. Our wholesale pricing is structured to be cost - effective for large - scale orders, and our flexible production capabilities allow us to accommodate small - batch custom projects. Whether it's for a specialized industrial machine or a unique electronic device, we can develop locking standoffs that meet your exact specifications.

Our locking standoffs represent a reliable and innovative solution for ensuring component stability. By choosing our products, customers can eliminate the risk of component loosening, enhancing the safety and reliability of their systems. Contact us today to explore how our custom - designed locking standoffs can meet the specific requirements of your projects, backed by our expertise in fastening technology and a commitment to delivering high - quality, tailored solutions.