Stainless standoff screws are highly sought - after fastening components, prized for their exceptional corrosion resistance, durability, and aesthetic appeal. Constructed from various grades of stainless steel, such as 304 and 316, these screws are designed to perform reliably in harsh environments where exposure to moisture, chemicals, or salt is common. At [Company Name], we utilize state - of - the - art manufacturing processes, including cold - forming and precision threading, to produce stainless standoff screws that exceed industry standards in quality and performance.

The production of our stainless standoff screws begins with the selection of premium stainless steel alloys. Grade 304 is commonly used for general - purpose applications, offering good corrosion resistance in most indoor and mild outdoor environments. For more demanding applications, such as marine, coastal, or chemical processing environments, we use grade 316, which contains molybdenum for enhanced resistance to pitting and crevice corrosion. After material selection, the screws are cold - formed to shape, a process that enhances their mechanical properties by aligning the grain structure of the metal. Precision threading is then carried out to ensure accurate and consistent thread engagement. Surface finishes, such as passivation to remove surface contaminants and enhance corrosion resistance or electropolishing for a smooth, shiny appearance, are applied as per customer requirements. Rigorous quality control procedures, including ultrasonic testing for internal defects, salt spray testing for corrosion resistance, and torque testing for thread integrity, are performed to guarantee the highest product quality.

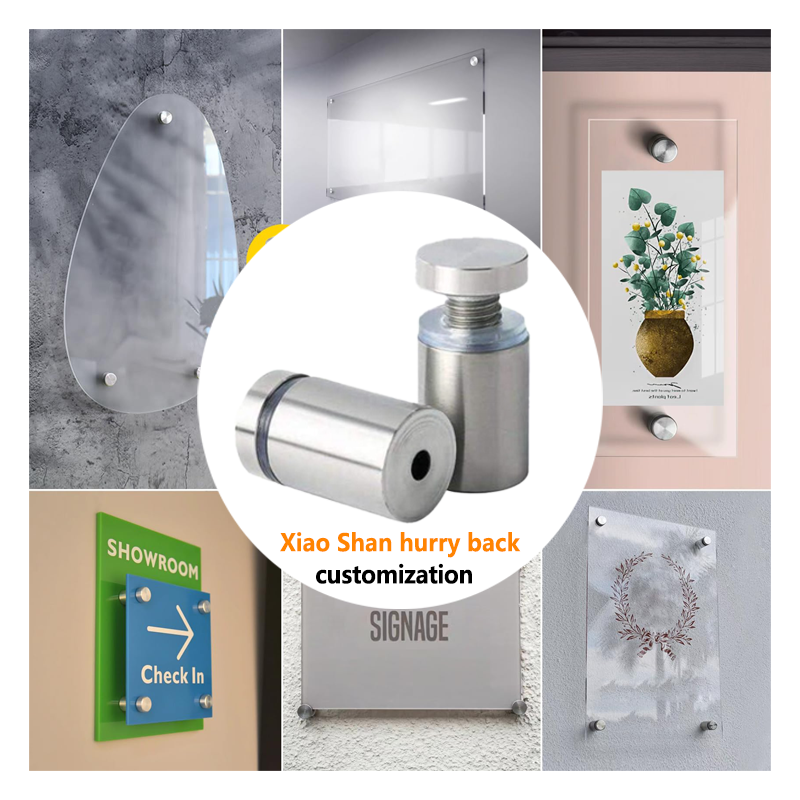

Stainless standoff screws are used across numerous industries. In the marine industry, they secure deck fittings, navigation lights, and other components, enduring the corrosive effects of saltwater. In the food and beverage industry, they are essential for equipment assembly due to their hygienic properties and resistance to cleaning chemicals. For architectural applications, they provide a sleek, modern look while ensuring the structural integrity of installations, such as glass facades and metal panels. Our stainless standoff screws are available in a wide range of sizes and styles, including standard and non - standard options, to meet the diverse needs of customers globally. We also ensure that our products comply with international standards, such as ASTM A320 for cold - headed stainless steel fasteners, enabling seamless integration into global supply chains.

Customization is a significant advantage of our stainless standoff screws. Clients can request specific stainless steel grades, unique thread pitches, custom lengths, or specialized head designs. We also offer custom surface treatments, such as colored anodizing for aesthetic purposes or PTFE coating for non - stick and low - friction properties. For branding, we provide logo - embossing services on the screw heads. Our wholesale pricing model is designed to be competitive for large - volume orders, and our efficient production and logistics processes ensure timely delivery to customers worldwide. Whether for small - scale projects or large - scale industrial applications, we can tailor our stainless standoff screws to meet your exact specifications.

Our stainless standoff screws embody the perfect blend of corrosion resistance, mechanical strength, and customization. By choosing our products, customers can rely on long - lasting, high - performance fastening solutions that maintain their integrity and appearance in challenging environments. Contact us to discuss how our custom stainless standoff screws can enhance the reliability and aesthetics of your projects, backed by our extensive experience in stainless steel fastener manufacturing and a dedication to customer - centric service.