Corrosion Resistance: The Foundation of Outdoor Deck Screw Performance

Why Corrosion Resistance Is Critical for Outdoor Deck Screws

How well deck screws resist corrosion really determines if they'll hold up over time or give out before the deck itself needs replacing. These screws face all sorts of harsh conditions daily - wet weather, extreme heat and cold changes, plus chemicals leaching out from pressure treated wood. When just one screw starts corroding, it doesn't take long before we see problems like rot spreading through the wood or composite boards popping up dangerously. The numbers back this up too. Industry data from last year shows that almost 4 out of every 10 decks needing repair within their first few years had issues traced back to bad fastener choices, and guess what? Corrosion was at the top of the list for these failures.

How Moisture and Weather Accelerate Metal Degradation in Deck Fasteners

The daily cycle of morning dew combined with seasonal freezing and thawing creates chemical reactions that actually eat away at metal surfaces over time. Along coastlines where salt gets into the air, this problem gets worse because saltwater conducts electricity better than fresh water does. That means when different types of metal come into contact, they corrode much faster than normal. We've seen cases where galvanized screws start showing signs of wear in as little as a year, whereas regular steel bolts without any protection tend to develop rust spots after only going through one wet season. The difference in material quality makes all the difference in how long hardware lasts before needing replacement.

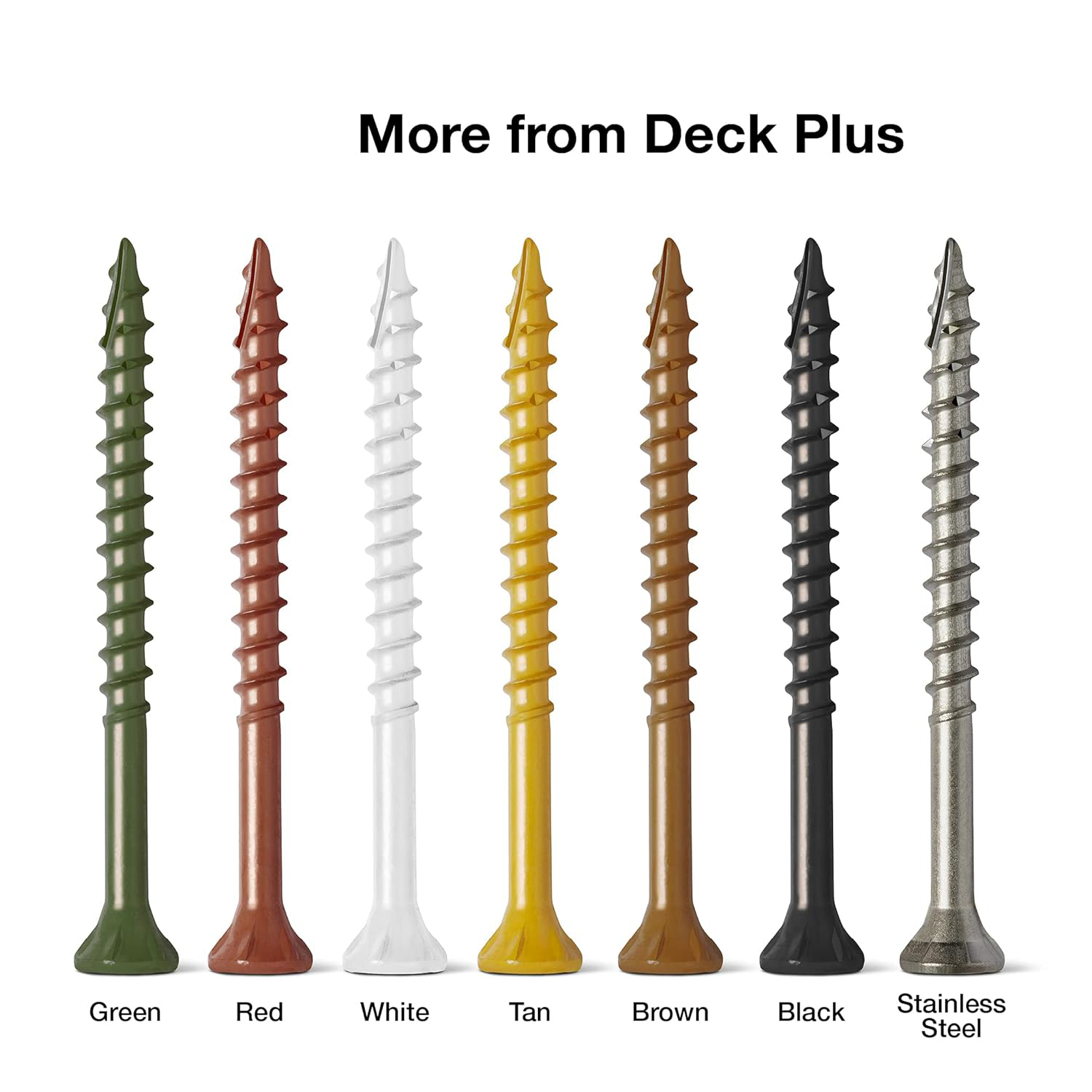

Comparing Corrosion-Resistant Materials: Stainless Steel vs. Galvanized vs. Silicon Bronze

| Material | Corrosion Resistance | Typical Lifespan | Best Applications |

|---|---|---|---|

| 304 Stainless Steel | High | 10–15 years | Inland climates, ACQ lumber |

| 316 Stainless Steel | Exceptional | 20+ years | Coastal areas, saltwater exposure |

| Hot-Dip Galvanized | Moderate | 3–7 years | Dry climates, budget projects |

| Silicon Bronze | Excellent | 15–25 years | Hardwoods, marine-grade composites |

Long-Term Performance in Coastal Environments and High-Humidity Regions

Salt air environments really bring out the strengths of 316 stainless steel because it contains around 2 to 3 percent molybdenum, something that helps fight off those pesky chloride pits. When looking at deck construction near coastal areas, especially within a mile of the beach or on piers, many builders have noticed that these 316 screws hold up much better over time compared to regular galvanized options. Some reports suggest they last about 70-odd percent longer before showing signs of wear. Now when we talk about places with lots of humidity like tropical regions, silicon bronze becomes the go to material. What makes it work so well? Well, it develops this natural patina over time that creates protection against corrosion without leaving ugly stains on white or light colored composite decks, which is definitely a plus for homeowners who care about aesthetics as much as durability.

Material Compatibility with Different Decking Types

Choosing the right screw material for your decking type prevents galvanic corrosion and ensures long-term stability.

Stainless Steel (304 and 316) for Pressure-Treated Lumber and ACQ Compatibility

Stainless steels like Type 304 and 316 stand up pretty well against corrosion caused by those ACQ treatments found in pressure treated lumber. Tests show that after spending about ten years along the coast, these types of screws still hold onto around 98 percent of their original tensile strength as reported by the American Wood Council back in 2023. What makes 316 grade steel really shine though is its increased nickel content which helps prevent those annoying pits from forming when exposed to saltwater. This gives it a clear edge over regular galvanized alternatives in areas where salt air is constantly attacking metal surfaces.

Galvanized and Coated Steel: Cost-Effective but Limited Lifespan

Hot-dip galvanized screws offer initial savings of 40–60% over stainless steel but lose effectiveness in humid climates, where zinc coatings degrade within 5–7 years. A 2022 corrosion study found these screws lost 53% of clamping force after repeated freeze-thaw cycles, making them unsuitable for permanent outdoor use.

Silicon Bronze for Marine-Grade and High-End Composite Applications

Silicon bronze demonstrates a corrosion rate of 0.5mm/year in ASTM B117 salt-spray tests, outperforming stainless steel in marine settings. It also avoids iron oxide staining on light composites and prevents electrolytic reactions in aluminum-reinforced systems due to its non-conductive nature.

Matching Deck Screw Materials to Composite, Capstock, and Hardwood Decking

- Composites: 410 stainless steel resists acid corrosion from recycled plastic content (pH 2.5–4.5)

- Capstock: Ceramic-coated screws prevent color transfer on capped polymer surfaces

- Hardwoods: Heat-treated steel (Rockwell C40+) maintains thread engagement in dense ipe and cumaru without stripping

A 2023 field study across 120 installations showed that properly matched screw materials reduced warping and fastener pops by 68%.

Mechanical Design Features That Ensure Durability and Ease of Installation

Self-drilling and self-countersinking tips for efficient, split-free installation

Deck screws today have those cool drill points built right in, so no need to pre-drill holes when working with tough woods like Ipe or composite materials. Some recent testing looked at around 12 thousand installations and showed these special tips cut down on board splitting problems by almost two thirds compared to regular screws without them. The self-countersinking feature means the screws sit nice and flat against the wood surface. And those washer heads? They spread out the pressure over about 40 percent more area than standard flat head screws do according to what Fastener Tech Quarterly reported last year.

Torx (star-drive) heads and their role in reducing cam-out and damage

The Torx T20 and T25 drive systems actually handle about 78 percent more torque compared to regular Phillips head screws. They pretty much stop that annoying problem called cam out, which happens when the driver slips off the screw head and strips it, especially common in pressure treated wood projects. According to field tests from the National Wood Flooring Association back in 2022, using Torx screws cuts down on installation problems by roughly 45%, plus they go into place about 30 something percent quicker than other types. Because of these benefits, most manufacturers of composite decking materials have started recommending Torx compatible fasteners in their installation guides. About 90% of them now specifically mention needing Torx for proper installation.

Thread geometry and head design optimized for wood and synthetic boards

| Feature | Wood Applications | Composite Applications |

|---|---|---|

| Thread Pitch | Coarse (8-10 TPI) | Fine (12-14 TPI) |

| Shank Design | Partially threaded | Fully threaded |

| Head Angle | 82° flat head | 100° bugle head |

Dual-threaded screws combine aggressive upper threads for quick penetration with fine lower threads that clear debris from pilot holes. This design increases pull-out resistance by 28% in pressure-treated pine and 31% in PVC boards (ARI 2023).

Proper Screw Dimensions and Installation Best Practices

Selecting the right screw length and gauge for joist-to-deck board connections

When it comes to getting good results from deck screws, they need to be long enough to reach through at least 2.5 times whatever thickness the decking has. Most folks find that 3 inch screws work well with those 1.5 inch composite boards commonly used these days. The 8 gauge variety (which measures around 0.164 inches) usually holds up fine for regular jobs, but if someone is building something really substantial, going with the thicker 10 gauge option (about 0.190 inches) makes sense. According to some tests done recently, using the right size fasteners can actually boost how much weight a deck can hold by roughly 40 percent compared to when people skimp on the size. That kind of difference matters a lot in the long run.

Balancing holding strength with risk of splitting in dense materials

Tapered threads reduce splitting by 30% in hardwoods and high-density composites. Pre-drilling pilot holes to 60–80% of the screw shank diameter prevents surface checking in dense woods like ipe while preserving 85% of withdrawal strength.

Weatherproof installation techniques to extend deck life

Countersinking screws 1/8" below the surface promotes proper water runoff and prevents pooling. Applying silicone sealant to screw holes before insertion creates a moisture barrier—field tests show this method cuts corrosion failure rates by 55% in coastal areas (Marine Construction Journal 2024). Always leave 1/4" gaps between boards to accommodate thermal expansion.

Building Code Compliance and Industry Standards for Structural Safety

IRC and APA Guidelines for Approved Deck Fasteners and Spacing

According to the International Residential Code (IRC), builders need to use either stainless steel or hot dip galvanized screws when making structural connections. There's also a requirement for at least 1/8 inch space between composite boards so they don't buckle under pressure. The APA, which stands for The Engineered Wood Association, has its own guidelines too. They say screws should go through joists about one and a half times deeper than the board itself is thick. For standard 5/4 decking material, this means getting at least 1.5 inches into the joist. These specifications help buildings stand up better against strong winds without lifting off their foundations.

Load-Bearing Requirements and Engineering Recommendations

Deck screws must support 1.5 times the design live load (typically 40–60 PSF) plus dead loads (10–15 PSF), as outlined in ASCE 7-22. Engineers commonly specify 10–12 gauge screws for ledger-to-house connections, requiring individual fasteners to exceed 300 lbs of shear strength in treated lumber applications.

Common Code Violations and Inspection Failures Related to Improper Screws

Per 2023 structural safety audits, 63% of deck failures involve undersized or corroded screws. Frequent violations include:

- Using interior drywall screws (non-corrosion-resistant) outdoors

- Spacing screws beyond 16" on-center in composite decking

- Mismatching screw coatings with ACQ-treated lumber, accelerating galvanic corrosion

Frequently Asked Questions

What makes 316 stainless steel ideal for coastal environments?

316 stainless steel is ideal for coastal environments due to its high molybdenum content, which protects against chloride-induced corrosion common in salt air.

Why are Torx screws preferred over Phillips screws for decks?

Torx screws are preferred because they can handle more torque without stripping, reducing the risk of cam-out, which is common with Phillips screws.

How do self-drilling screws benefit deck installation?

Self-drilling screws eliminate the need for pre-drilling, reducing installation time and minimizing the risk of wood splitting.

What is the advantage of using silicon bronze screws on marine-grade decks?

Silicon bronze screws develop a protective patina that resists corrosion in marine settings without staining, making them ideal for marine-grade applications.

How can I ensure my deck screws are corrosion-resistant?

Choose screws made from stainless steel or other corrosion-resistant materials, and consider coatings or sealants for added protection.

Table of Contents

- Corrosion Resistance: The Foundation of Outdoor Deck Screw Performance

- Material Compatibility with Different Decking Types

- Mechanical Design Features That Ensure Durability and Ease of Installation

- Proper Screw Dimensions and Installation Best Practices

- Building Code Compliance and Industry Standards for Structural Safety

-

Frequently Asked Questions

- What makes 316 stainless steel ideal for coastal environments?

- Why are Torx screws preferred over Phillips screws for decks?

- How do self-drilling screws benefit deck installation?

- What is the advantage of using silicon bronze screws on marine-grade decks?

- How can I ensure my deck screws are corrosion-resistant?