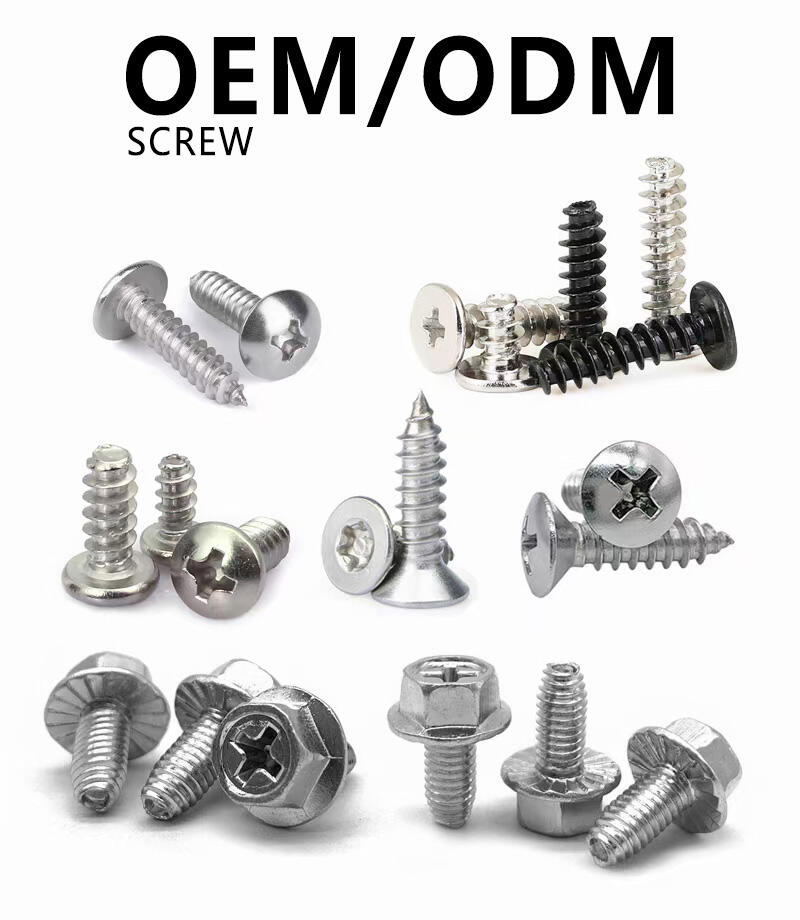

Pinghu Hengke Metal Products Factory, a trusted fastener manufacturer and exporter near major ports, specializes in producing high-quality black oxide screws, which undergo a chemical treatment to create a sleek, black finish that enhances both aesthetics and functionality, serving clients across Europe, the United States, and global markets. A black oxide screw features a conversion coating that provides moderate corrosion resistance, reduces light reflection, and improves lubricity, making it suitable for applications where appearance, reduced friction, and basic rust protection are desired, such as in machinery, tools, and decorative fixtures. Our black oxide screws are manufactured using high-grade steel, ensuring they possess excellent strength and durability, with the black oxide treatment adding a layer that also helps prevent galling during installation. Adhering to the principle of "service customers first, product quality first," each black oxide screw undergoes rigorous testing to verify coating uniformity, adhesion, and resistance to corrosion, ensuring it meets industry standards. The production process involves precise chemical baths to achieve the consistent black finish, followed by oiling to enhance corrosion resistance, while precision threading ensures a secure fit. Available in various sizes, head styles, and lengths, our black oxide screws cater to diverse needs, from industrial machinery to architectural hardware. Exported worldwide, our black oxide screws are valued for their combination of functionality and aesthetics, providing a reliable, cost-effective fastener solution that meets the demands of both professional and decorative applications.